Precision Lock Nuts

Price 150000 INR/ Piece

Precision Lock Nuts Specification

- Weight

- Variable, depends on size

- Tensile Strength

- High

- Metal Type

- Alloy Steel

- Density

- 7.85 Gram per cubic centimeter(g/cm3)

- Material Grade

- EN24

- Material

- High Grade Steel

- Structure

- Threaded

- Standard

- DIN 981

- Shape

- Round

Precision Lock Nuts Trade Information

- Minimum Order Quantity

- 10000 Pieces

- Supply Ability

- 1000000 Pieces Per Week

- Delivery Time

- 7 Week

About Precision Lock Nuts

Precision Lock Nuts are employed to preload, regulate and secure gears, bearings and many other power transmission produces to shafts as well as spindles with an increased degree of stiffness. These nuts have machined internal threads as well as sturdy faces that render strong metal-to-metal locking without bend or distortion Precision Lock Nuts are occasionally referred as bearing locknuts as the dimensions of these products are made to relate with standard bearing sizes.

Engineered for Precision and Durability

Crafted to meet DIN 981 standards, these precision lock nuts offer exceptional locking stability for bearings and machine shafts. Made from alloy steel of grade EN24, each nut delivers high tensile strength, ensuring reliable performance in critical assemblies. The corrosion-resistant silver finish enhances durability, while the H7 tolerance guarantees a consistent fit. Suitable for a broad temperature range and diverse mechanical setups.

Versatile Applications & Hassle-Free Packaging

Precision lock nuts are ideal for industrial sectors that require secure and sturdy fastening, such as automotive, heavy machinery, and manufacturing. Their temperature resistance up to 400C makes them suitable for both standard and high-heat applications. Each lock nut is delivered boxed for protection during transit, maintaining product integrity for suppliers, exporters, and wholesale distribution in India.

FAQs of Precision Lock Nuts:

Q: How do precision lock nuts ensure secure locking for bearings and machine shafts?

A: Precision lock nuts apply uniform pressure with a threaded structure, meeting DIN 981 standards, and an H7 tolerance. This ensures a tight, stable grip on bearings and shafts, reducing the risk of loosening during operation even under high stress or vibration.Q: What are the major benefits of choosing EN24 high-grade steel lock nuts for industrial use?

A: EN24 grade steel provides high tensile strength, durability, and improved resistance to mechanical wear. Combined with a corrosion-resistant precision ground finish, these lock nuts offer a long service life and reliable performance in demanding environments.Q: When should I use these precision lock nuts in my machinery?

A: Use these lock nuts when you require secure locking for bearings or shafts, especially in applications where stability, corrosion resistance, and temperature resilience (up to 400C) are essential. Their robust build makes them ideal for automotive, manufacturing, and heavy equipment sectors.Q: Where are these precision lock nuts typically supplied from, and who can use them?

A: These lock nuts are manufactured, exported, and supplied from India, catering to a global clientele. They are suitable for machinery manufacturers, exporters, industrial suppliers, and wholesalers dealing with high-precision mechanical components.Q: What is the manufacturing process for achieving precision ground surface finish and H7 tolerance?

A: The nuts are produced through precision machining and high-grade alloy steel treatment, followed by grinding to achieve a smooth, consistent surface. Rigorous quality checks ensure an H7 tolerance, which assures accurate dimensions and fit for dependable locking.Q: How does the corrosion resistance benefit long-term usage?

A: Corrosion-resistant properties protect the nuts from rust and environmental degradation, ensuring prolonged durability and reduced maintenance needs, even in humid or chemically harsh industrial conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conduit Fitting Category

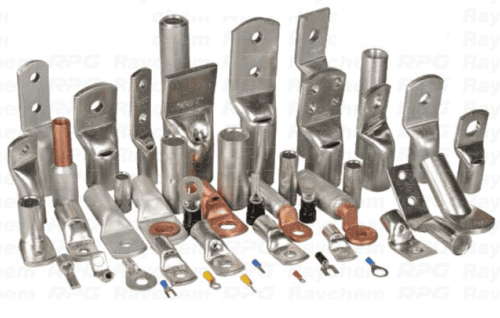

Cable lugs

Minimum Order Quantity : 1000 Pieces

Structure : Others, Tubular

Standard : IEC 612381

Shape : Ring

Metal Type : Copper

Material : Other, Electrolytic Grade Copper

PVC Corrugated Window

Minimum Order Quantity : 10000 Pieces

Structure : Others, Corrugated Panel

Standard : ISO 9001, IS 14772

Shape : Rectangular

Metal Type : Other, Nonmetal (PVC)

Material : Other, Polyvinyl Chloride (PVC)

Stainless Steel Clip Steel

Structure : Others, Rigid

Standard : Industrial Standard

Shape : Clip

Metal Type : Steel

Material : Stainless Steel, Other

Locknut Hexagonal

Structure : Others, Threaded

Standard : DIN 439

Shape : Hexagonal

Metal Type : Stainless Steel

Material : Steel, Other

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free